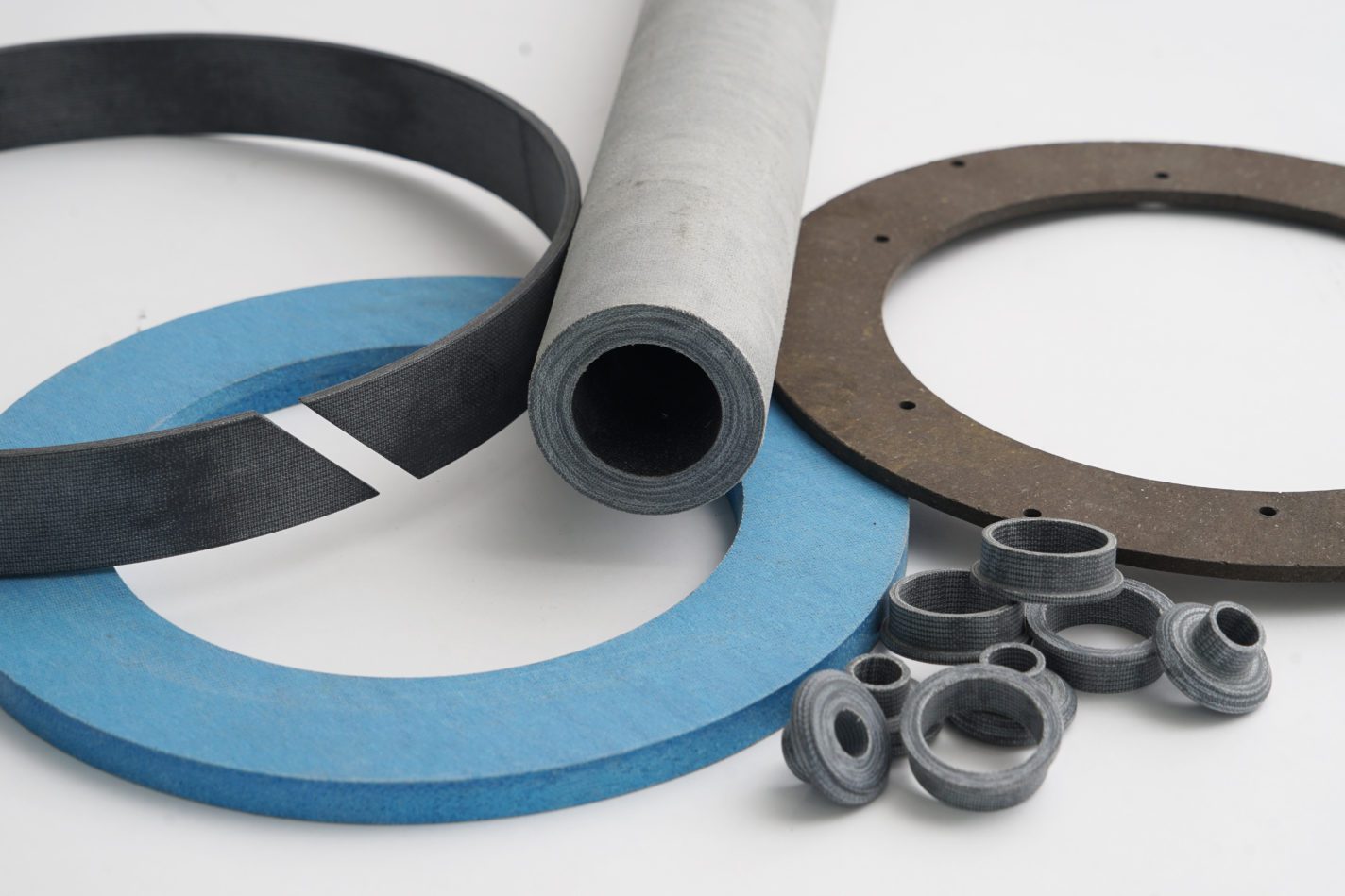

Composite bearing materials

This composite engineering material is manufactured from synthetic fibres and thermosetting resins. All grades are available with solid lubricant incorporated. The different grades contain either graphite, PTFE or molybdenum disulphide dispersed evenly throughout the material, so that wear on the surface of a component continually releases further lubricant.

The composite bearing materials offer design engineers an attractive alternative to the traditional materials used throughout industry for bushes, bearings, wear pads and many more applications. They are only one sixth the weight of steel, easily machined, and have exceptional dimensional stability, even in wet conditions. Special performance or properties such as fire retardance or acid resistance can be obtained through variations in either resin or fabric reinforcement.

The materials are highly recommended for use in situations where other forms of lubricant are undesirable, erratic, intermittent or non-existent. In addition, they offer an improved performance in situations where it is difficult to maintain lubricant films. The grade T100, in particular, has an extremely low rate of moisture absorption and negligible dimensional change, making it ideal for use in submerged water applications. Contact us for further information.