AlphaSystem™ by Alpha Diagnostics – Machine Condition-Based Monitoring from Switzerland

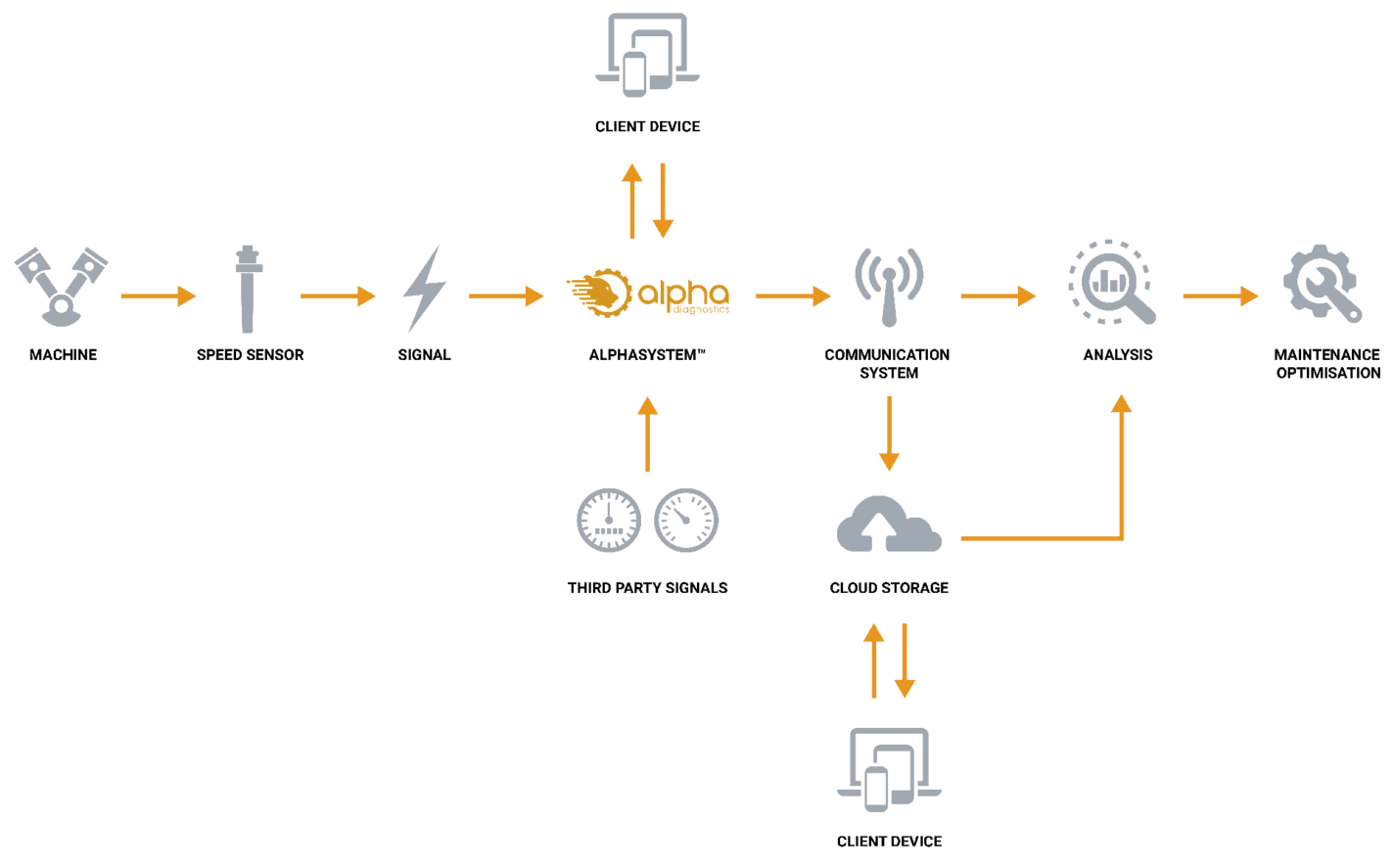

Alpha Diagnostics is a leading expert in the measurement and analysis of torsional vibration, as well as designing easy-to-use maintenance tools for in-house maintenance teams. Its vision is to provide the most sustainable and cost-effective maintenance of machines with a single diagnostics algorithm – AlphaSystem™.

AlphaSystem™ is the most advanced independent solution for condition-based monitoring of rotating and reciprocating machines. It is designed to elevate in-house teams into machine condition experts and enable more sustainable, reliable and cost-effective maintenance operations.